Vanlife Conversions review – building Biggie Small

This post is about our experience working with Vanlife Conversions, and how we went from an empty panel van to an offgrid tiny home on wheels.

Vanlife Conversions are a small, independently owned company based in Essex, UK that specialises in, and builds bespoke van builds. We first made contact with Oli and Emily from Vanlife Conversions in August 2019, by replying to one of their stories about how wide a bed was in the build they were working on at the time. At this point, a van upgrade was just a pipe dream but we both enjoyed following along with other people’s builds on YouTube and Instagram whilst traveling in our VW T5.

However, things escalated pretty quickly and by September we were discussing layouts and pricing over Instagram DMs. Initially, we planned our van conversion with a VW Crafter as the base van. We spent the next few months doing hundreds of hours of research, looking at layouts and making a decision on a base van. We then listed our T5 for sale, ordered a new van (a Peugeot Boxer L4 H3 / Promaster), and paid a deposit to Vanlife Conversions to secure our build slot in January 2020. It was around this time that we created ‘The Road Two Spoons’ as a way to document our journey and future adventures with the new van on completion. We decided to use Vanlife Conversions as we had very select requirements for both the layout and features.

Having the option to do a totally bespoke build purely for us was extremely appealing. We also loved the hand-made aesthetic vs a more traditional motorhome look with a furniture board build/finish.

Our build slot was booked for May but unfortunately due to the Covid pandemic and factory closures, we had to push the date back several times. Oli and Emily were very accomodating with moving the time slots around considering they also had other customers booked in before and after our build slots.

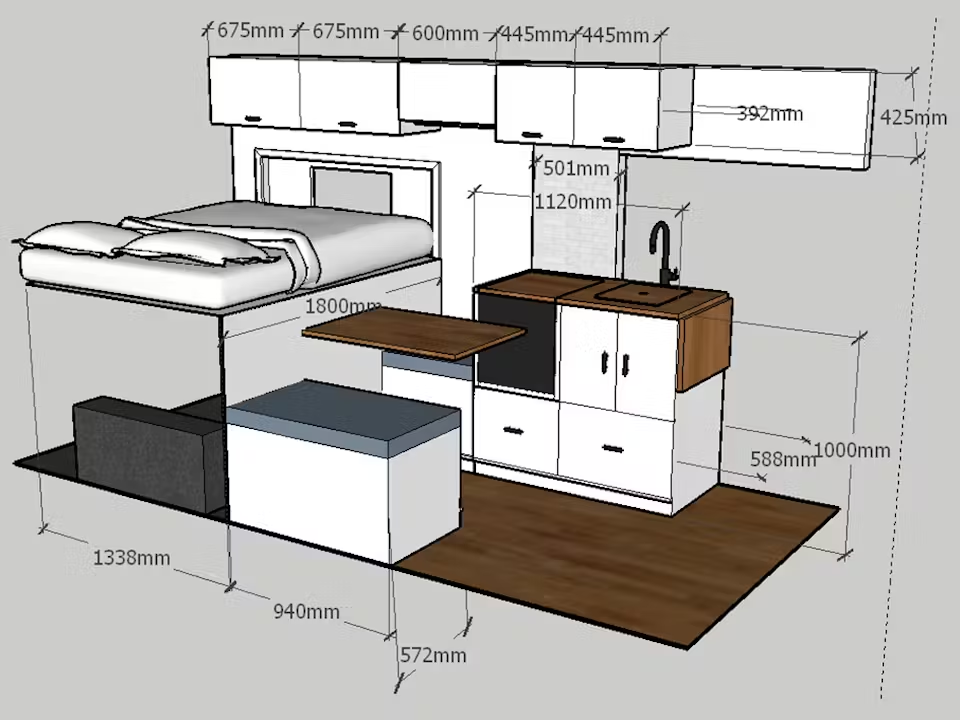

Whilst we waited for the new van to arrive, we had a video call to discuss the build in general and any specific aesthetic styles or features we wanted to include. Once we had provided a rough layout Oli provided us with a more accurate 3D rendering of the layout in the correct sizes/dimensions. We loved that Oli and Emily were always working to improve the layout or build where possible and fed back throughout the entire process with suggestions.

Eventually, the new van (Biggie Small) arrived and we drove it down to Essex from our base in Wales. Unfortunately, due to Jess’ work she was unable to make the initial drop off and so didn’t meet Oli or Emily face to face until later in the process. Oli and Emily seemed really excited about the new build, and it was the first opportunity they’d had to work on a brand new van. Some of the factory changes like twin single seats and the bulkhead delete meant there was less to strip out (and clean) prior to starting work.

Below: Oli and Emily from Vanlife Conversions in our van, Biggie Small.

Prior to dropping off Biggie Small we migrated all our communications from Instagram to WhatsApp so everyone could be in the same group. From then on we used WhatsApp and continued to do so up until completion. Having a single group chat was a really easy way for us to see updates, and confirm tweaks on the fly. We reserved emails for important things like quotes and invoices. Outside of a pandemic, there are multiple opportunities to go and see the van during the build process. We managed to get one visit in fairly early on. The windows were in, all of the solar panels, the roof fans, and the WiFi antenna had been installed onto the roof. They were also just finishing the insulation and first-fit electrics. Standing in Biggie Small, with the layout marked out onto the floor and walls in tape was the first time we were able to visualize the final layout.

This trip was extremely beneficial to us as we ending up revising the sizes of almost everything.

- We made the bed wider

- We changed the sizes of the bench seats

- We made the wardrobe smaller

- We made the shower/toilet room as small as possible, which also included adding an angled corner to save additional space between the room and the kitchen area

After our visit we spent the next few weeks waiting (impatiently) for updates on the build. We seemingly spent all day checking our phones hoping for a picture or Instagram story of the build to pop up. We tended to get a few photos and odd videos towards the end of each week. We would have liked to have even more updates on every aspect of the build but appreciate that some actual work needs to happen too.

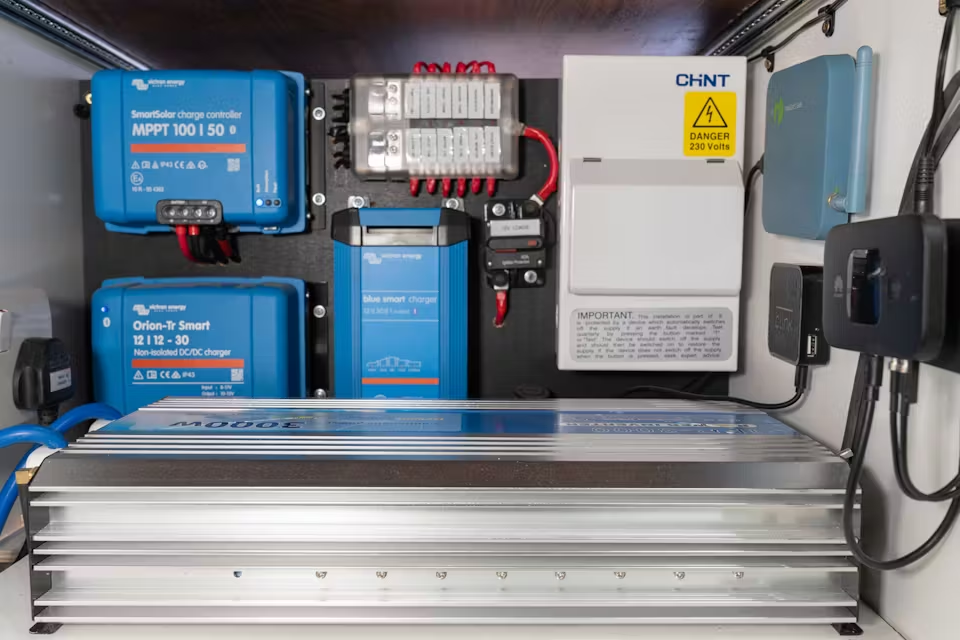

During the build process, we had several calls with tweaks or changes that were required, some of these were new suggestions from Oli and Emily. The biggest change was to relocate the entire electrical setup from the side of the garage to the center. This allowed the frame to be used as part of the table support but also meant that all of the electrical equipment would be separated from all the wet sandy gear that would end up in the garage. The result is a super tidy, and accessible electrical cabinet which we access from within the van. This houses the batteries, all of the charge controllers, our fuse board and a few other gadgets like the Motorhome WiFi setup. You can learn more about our electrical system here.

Towards the end of the build, the updates and communication levels dropped, they like to keep the final build and finishing touches a surprise until the van is collected. From drop off to collection the entire process was just over 3 months. Our build was slightly delayed due to part shortages with suppliers but we were kept in the loop with regards to these and provided with alternative options when required.

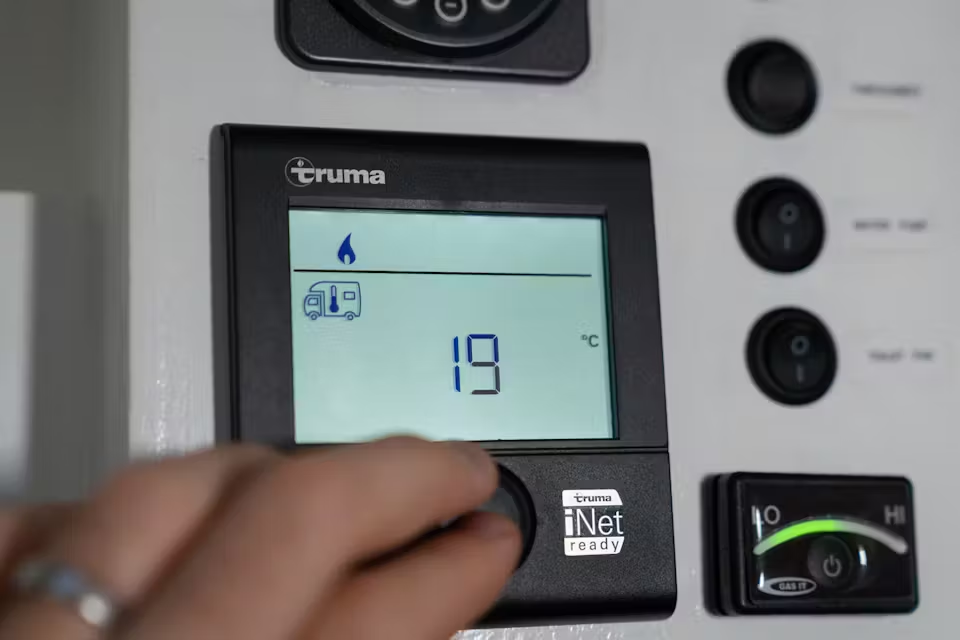

On collection, we spent an hour or two going through the van’s features and some of the more specifics on certain features, like programming the combi boiler and setting up our phones to work with the Victron controllers over bluetooth. We also had a printout containing general instructions and advice for using the van.

After saying our thanks and goodbyes we headed back to Wales, excited about our first adventure. For our first trip we spent a week off grid around the Brecon Beacons, Mid Wales, and the Elan Valley. This was a great opportunity to test all of the features and get used to driving the van down all the hairy singletrack roads which we love in Wales. During this trip, much like with buying a new home we did find a few niggles and snags with the build. Our main issue was that the catches used on the cupboards and drawers were not strong enough and on the winding roads and tight bends the doors were flying open – this shows the importance of a proper, shorter road test prior to simply disappearing into the sunset or getting straight on the channel tunnel. Each time we found an issue or noticed something, we fired a message over on the WhatsApp group to document it prior to arranging a visit back to Vanlife Conversions. Unfortunately, we soon fell back into lockdowns and were unable to get the fixes resolved for quite some time. Once lockdowns were lifted we dropped the van back for Oli and Emily to work on the list of fixes/changes that were required.

Some of the items that required fixing/changes:

Without realising, we had managed to blow an inline fuse in the cable that powered the toilet fan. The solution was to remove the inline fuse and have it solely managed on the fuse board.

Initially, we had stick-on tiles on the splashback to help save weight, unfortunately, with the changes in temperature and humidity in the van, these started to peel back in a few places. The solution was to replace these with real metro tiles and a flexible grout.

One of our MaxxAirr Fan shades didn’t quite click into place and decided that the bumpy Welsh single track roads didn’t suit it and managed to rattle loose. The solution was to modify the ceiling to allow this to properly snap into place.

On the bathroom wall which had the heater vent, we experienced some bubbling on the material and the panel deformed slightly. The solution here was to replace the entire wall with a new, thicker sheet.

As previously mentioned we had some moments with the pan drawers and overhead cupboards attempting to offload their contents whilst driving. It’s not ideal watching your camera bag fly out of a cupboard and into the kitchen counter. Vanlife Conversions not only replaced every catch in the van with new, stronger magnets but also updated all of our doors and cupboards with soft close struts free of charge.

Whilst the van was back with them we also had a draft excluder made up, and an Autoterm D4 diesel heater installed.

We’ve had no issues with any of the above fixes since they were put in place and we really appreciated the upgraded struts on all the cupboards.

After a couple of visits back to Essex to get everything resolved we’ve now had Biggie Small out on the road for a few months and everything is working perfectly. We are hoping that the next time we meet Oli and Emily in person is parked up with our van doors facing each other in some remote location for a social.

We understand that commissioning a van build is not going to suit everyone’s style or budget, in the same way that a DIY build would not have worked for us. We are super grateful to Oli and Emily from Vanlife Conversions for bringing our once distant pipe dream into a reality. We have already spent several months with Biggie Small traveling around Wales and have created hundreds of memories as a family, which for us, is what it is all about.

If you are interested in or planning an off grid van conversion and want to commission the build rather than DIY we would highly recommend considering Vanlife Conversions.

‘It was a pleasure to work with Marcus and Jess and create their dream van to facilitate their travel and lifestyle plans. We loved the design and layout that they had in mind from the beginning which was perfect for full time living and it was great fun to be able to install so many high spec appliances. Thanks for choosing us and allowing us to bring your concept to life, we can’t wait to follow all your adventures in Biggie Small!’

Oli and Emily, Vanlife Conversions